ERRORS IN INDUCTION-TYPE ENERGY METERS AND THEIR COMPENSATION

1.Phase-angle Error

2.Error due to Friction at Light Loads

3.Creeping Error

4.Error due to Change in Temperature

5.Error due to Voltage Variations

1.Phase-angle Error:

The meter will indicate true energy only if the phase angle between the pressure coil flux φ and the supply voltage V is 90°. This requires that the pressure coil winding should be designed as highly inductive and its resistance and iron losses should be made minimum. But, even then the phase angle is not exactly 90°, rather a few degrees less than 90°. Suitable adjustments can be implemented such that the shunt magnet flux linking with the disc can be made to lag the supply voltage by an angle exactly equal to 90°.

A. Shading Coil with Adjustable Resistance: This is the arrangement where an additional coil (shading coil) with adjustable resistance is placed on the central limb of the shunt magnet close to the disc. Main flux created by the shunt magnet induces an emf in this shading coil. This emf creates its own flux. These two fluxes result in a modified flux to pass through the air gap to link the disc and thus produce the driving torque. With proper adjustment of the shading coil resistance, the resultant flux can be made to lag the supply voltage exactly by an angle of 90°.

The pressure coil, when excited from the supply voltage V, carries a current IP and produces an mmf (AT)pt which in turn produces the total flux φpt. The flux (φ)pt lags the supply voltage V by an angle φ which is slightly less than 90°. The current IP produces a flux φpt that is in same phase as IP. The flux φpt gets divided in two parts, φ and φp. The portion of flux φ passes through the side gaps, and remaining portion of the flux, i.e., φp passes through the disc and also the shading coil. Due to linkage with the time varying flux, an emf Esc is induced in the shading coil that lags behind its originating flux φp by 90° (i.e. ESC is 180°) lagging behind the supply voltage V. This emf circulates and eddy current Isc through the shading coil itself. Isc lags behind the emf Esc by an angle λ that depends on the impedance of the shading coil. The shading coil current Isc produces an mmf (AT)sc which is in phase with Isc. The flux φppassing through to the disc will thus be due to the resultant mmf (AT)p which is summation of the original mmf (AT)pt and the mmf (AT)sc due to the shading coil. This flux φp will be in phase with the mmf (AT)p. The flux φp can be made to lag the supply voltage V by exactly 90° if the mmf (AT)p or in other words, the shading coil phase angle λ can be adjusted properly. The shading coil phase angle can easily be adjusted by varying the external resistance connected to the shading coil.

B. Copper Shading Bands:

A similar result of lag adjustment can be obtained by the use of copper shading bands placed on the central limb of the shunt magnet. Such an arrangement is shown in Figure 8.10. Following the same arguments, the resultant flux (φ)p crossing over to the disc can be made to lag the supply voltage V by exactly 90° by proper adjustment of the mmf produced by the copper shading bands. Adjustments in this case can be done by moving the shading bands along the axis of the limb. As the bands are moved upwards along the limb, they embrace more flux. This results in increased values of induced emf, increased values of induced eddy current and hence increased values of the mmf produced by the bands. Similarly, as the bands are moved downwards, mmf produced by the bands is reduced. This changes the phase angle difference between (φ)p and (φ)pt, as can be observed. Thus, careful adjustments of the copper shading bands position can make the phase difference between the supply voltage V and resultant shunt magnet flux (φ)p to be exactly 90°.

2.Error due to Friction at Light Loads:

Friction in bearings can pose serious errors in measurement of energy in the form of that it will impede proper movement of the rotating disc. This problem is particularly objectionable at low loads, when the driving torque itself is very low; therefore, unwanted friction torque can even stop the disc from rotating. To avoid this, it is necessary to provide an additional torque that is essentially independent of the load, to be applied in the direction of the driving torque, i.e., opposite to the frictional torque to compensate for the frictional retarding torque. This is achieved by means of a small vane or shading loop placed in the air gap between the central limb of the shunt magnet and the aluminum disc, and slightly off-centre from the central limb. Interactions between fluxes which are linked and not linked by the shading or compensating vane and the currents they induce in the disc result in a small driving torque that can compensate for the frictional retarding torque. The value of this small additional torque can be adjusted by lateral movement of the vane in and out of its position in the air gap.

3.Creeping Error: In some meters, a slow but continuous rotation of the disc can be observed even when there is no current flowing through the current coil, and only pressure coil is energized. This is called creeping. The primary reason for creeping is due to over-compensation for friction. Though the main driving torque is absent at no-load, the additional torque provided by the friction compensating vane will make the disc continue to rotate. Other causes of creeping may be excessive voltage across the potential coil resulting in production of excessive torque by the friction compensating device, or vibrations, and stray magnetic fields.

Creeping can be avoided by drilling two holes on the aluminum disc placed on diametrically opposite locations. Drilling such holes will distort the eddy current paths along the disc and the disc will tend to stop with the holes coming underneath the shunt magnet poles. The disc can thus creep only till a maximum of half the rotation till one of the holes comes below the shunt magnet pole. This effect is however, too insignificant to hamper disc movement

during normal running operations under load.

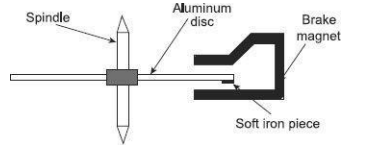

Creeping can also be avoided by attaching a tiny piece of iron to the edge of the disc. The brake magnet in such a case can lock the iron piece to itself and prevent creeping of the disc. Once again, this action is too insignificant to hamper disc movement during normal running operations under load.

4.Error due to Change in Temperature:

Errors introduced by variation of temperature in induction-type energy meters are usually small since the various effects tend to neutralize each other. An increase in temperature increases the pressure coil resistance, thereby reducing pressure coil current and reducing pressure coil flux. This will tend to reduce the driving torque. But the flux of the brake magnet also reduces due to increase in temperature, thereby reducing the braking torque. Again, an increase in temperature increases the resistance to eddy current path in the disc, which reduces both driving torque and braking torque. The various effects thus tend to neutralize each other.

The effects of increasing temperature, however, in general cause the meter to rotate faster and hence record higher values. Temperature effects thus need to be compensated for by using temperature shunts in the brake magnet.

5.Error due to Voltage Variations:

Voltage variations can cause errors in induction-type energy meters mainly due to two reasons: At too high voltages, the relationship between the supply voltage V and the shunt magnet flux φp no longer remain linear due to saturation of iron parts, and For sudden fluctuations in supply voltage, the shunt magnet flux φp produces a dynamically induced emf in the disc which in turn results in a self-braking torque and the disc rotation is hampered.

Compensation for voltage variation is provided by using a suitable magnetic shunt that diverts a major portion of the flux through the disc when the voltage rises, thereby increasing the driving torque to overcome the self-braking torque. Such compensation can be achieved by increasing the reluctance of the side limbs of the shunt magnet. This is done by providing holes in the side limbs.